In the production of tobacco packaging printing, curling of paper can lead to serious problems during post-processing and use. For instance, curled sheets can increase positioning errors during downstream processes such as cutting, hot stamping, and die-cutting, which can result in paper jams and machine downtime, severely affecting the efficiency and quality of subsequent processing. Once the printed sheets are processed into individual finished tobacco packages, curling can complicate the feeding process in box gluing machines and automatic packaging machines. Generally, lower basis weight papers (like coated paper) are more prone to curling than higher basis weight papers (like whiteboard paper). Therefore, ensuring the flatness of printing paper during the processing and storage stages is a crucial issue we must address.

- Relationship Between Paper Stiffness and Curling The stiffness of paper with the same basis weight depends on the type of pulp fibers used during production, including their thickness and length. Coarse, long fiber papers typically have better stiffness than fine, short fiber papers. Additionally, the paper-making process and structure also affect stiffness; for example, a “sandwich” structure paper with three layers has better stiffness than a “solid” structure paper. Curling caused by external forces during winding is difficult to correct during the flattening process, especially when using small core rolls, as the paper close to the core tends to curl more severely.

The characteristic of curling due to winding is that it occurs in the fiber direction, which provides a clear method for identifying whether a product has this type of curling.

- Relationship Between Paper Moisture Content and Curling Typically, the standard moisture content of paper immediately after leaving the paper machine is around 7% ± 2%. However, the moisture content can change during storage and printing processes, which is a primary cause of paper curling; over 90% of curling issues are attributed to this factor. Moisture is mainly retained between the fibers of the paper. Thus, increases or losses in moisture can lead to changes in the distance between fibers, predominantly affecting the transverse dimensions of the paper. When moisture content changes uniformly, it only leads to changes in the transverse dimensions, which needs to be avoided in printing registration, but does not cause curling. Curling occurs due to uneven moisture content changes within the paper.

Uneven moisture content changes can occur in two main scenarios. For instance, if the edges of a sheet or roll absorb or lose moisture unevenly, problems like “leaf-edge” curling (where the edges absorb moisture) or “tight-edge” curling (where the edges lose moisture) may arise. Additionally, when one side of the paper is treated with printing ink, which blocks the capillary pores on the printing side, while the non-printing side remains untreated, significant differences in moisture absorption capabilities can occur between the two sides. Prolonged exposure to an unsuitable humidity environment inevitably leads to transverse curling: when absorbing moisture, the fibers on the non-printing side expand more than those on the printing side, causing the paper to curl towards the printing side. Conversely, when moisture is lost, the non-printing side shrinks more than the printing side, resulting in curling towards the non-printing side.

Moreover, the widespread use of aluminum foil transfer paper in current packaging can lead to curling issues due to the layered construction of the printing surface (which consists of an aluminum layer, adhesive layer, etc.) that impedes moisture loss from the printing side. In low-humidity environments, this can result in curling towards the non-printing side, while in high-humidity environments, curling towards the printing side is more likely. Therefore, transverse curling is an inevitable result of uneven moisture content changes, providing a useful method for diagnosing the causes of transverse curling.

When the production location of the paper differs from the usage location, especially across varying regions or seasons, or when comparing air-conditioned and non-air-conditioned environments with different humidity levels, curling issues are likely to arise.

In the commonly used wet composite production processes for composite papers and transfer papers (where the surface is coated with water-based adhesive, the back is coated with waterproof adhesive, and then dried), improper control of adhesive moisture content, composite speed, and drying stages can lead to significant moisture discrepancies between the two sides of the composite or transfer paper, causing curling in unpredictable directions.

Additionally, other curling causes can arise in paper produced with composite materials. For example, when paper is laminated with plastic, excessive lamination temperatures or excessive traction forces from the plastic film can deform the plastic, resulting in curling after the composite has solidified or during cutting or film removal.

Explore our book printing services on the Printing in China page.

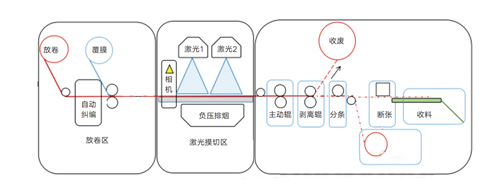

Anti-Curling Measures To resolve curling caused by winding, one approach is to select rolls of paper with large diameter cores at the time of ordering. Moreover, using humidifying devices and anti-curling devices on printing machines can help correct the issue. Humidifying allows moisture to penetrate the spaces between the paper fibers, increasing the distance between them. This loosening of fibers quickly reduces stiffness, allowing previously curled fibers to flatten out. However, controlling the effectiveness of humidifying devices on printing machines is challenging, and during high-speed operations, the surface coatings of the printed paper can impede rapid moisture absorption, making it hard to ensure flatness. Cost also remains a significant barrier to this method’s adoption in the industry.

Another method involves passing the curled paper’s reverse side through a guide roller with a diameter less than 50 mm and a large wrap angle, utilizing mechanical force to reverse the deformed fibers and achieve flattening. Additionally, the anti-curling device can automatically adjust the wrap angle based on the position of the paper in the roll, allowing for size adjustments to the reversing force according to the degree of curling, thereby preventing over-correction.

Comments

September 11, 2025 14:39

Many thanks regarding submitting this kind of fantastic write-up! I came across your internet site perfect for my own wants. It includes great and also beneficial content. Maintain the nice perform! Xenical