A bottle of high-quality wine is like a piece of exquisite artwork, and in this regard, the wine bottle and label play a crucial role. In the field of packaging printing, the printing process for wine labels is highly regarded. Here is an exploration of wine labels and their printing techniques.

Wine labels typically include information such as the winery’s name, the wine’s name, variety, volume, alcohol content, country of origin, production year, and bottling location. For consumers, these details are very important. The design of the wine label often features the winery’s logo, particularly noble emblems, royal seals, or depictions of the winery’s landscape and architecture. Additionally, since each year’s wine is printed with its vintage, many wine enthusiasts keep the beautifully designed labels with production years for later enjoyment and remembrance.

With so much information contained on such a small wine label, how can it be beautifully presented? Modern narrow-web rotary printing technology, which uses high-tech methods, can fully showcase the details of the wine label.

Printing of the Main Image on Wine Labels The main design on a wine label usually features intricate, exquisite, and classical patterns. Offset printing is the most suitable method for handling these designs, as it offers excellent halftone reproduction and the ability to reproduce fine text and lines. Furthermore, offset printing technology has been fully developed, and its supporting raw materials are well-established, making it a cost-effective option.

Printing Other Parts of the Wine Label For smaller text or security microtext and patterns, offset printing can be used. If the label includes standard text, barcodes, and color blocks, flexographic printing is a good choice.

Post-Printing Processing for Wine Labels Wine labels need to convey a sense of nobility and stability, so after printing, they often undergo additional finishing processes. For example, gold and silver effects can be added to the company logo or decorative lines using cold transfer or hot foil stamping techniques.

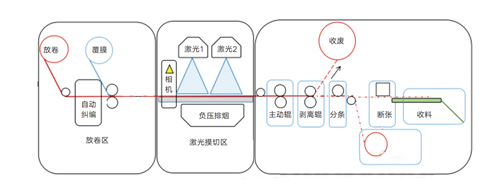

In addition, the wine labels undergo processes such as embossing, die-cutting, waste stripping, slitting, and rewinding.

The first color group uses flexographic printing or screen printing for the base layer on transparent wine labels. The second, third, fourth, and fifth color groups use offset printing for fine halftone images. The sixth color group employs screen printing for special effects. The seventh color group uses flexographic printing for text and color blocks. The ninth color group utilizes cold transfer or hot foil stamping to achieve gold and silver effects. The tenth color group applies flexographic printing for gloss coating. Subsequent color groups include embossing, die-cutting, waste stripping, slitting, rewinding, and other processes. Since platform exchange technology is used, various printing and processing methods can be switched freely, allowing for flexible adjustments in the process layout.

Explore our book printing services on the printing in China page.

Additionally, high-tech applications on wine labels also rely on modern narrow-web rotary printing technology. For example, the double-layer wine label is a typical use of advanced printing technology, where the first layer can be easily removed, allowing consumers to collect it or easily find the same wine in a crowded wine shop. The second layer provides detailed information about the wine’s characteristics and the winemaker’s evaluation.

Wine brand names and production years are often the most eye-catching elements for consumers. By using screen printing, a three-dimensional effect and vivid, saturated colors can be achieved, making it easier to attract consumer attention.

Comments

No comments yet. Be the first to react!