In the WorldSkills competition for the Printing and Media Technology category, the “Digital Printing Color Matching” contest has emerged as one of the challenging aspects affecting the scores of participants in recent years. As a guiding teacher for the Printing and Media Technology project, I have devised an effective method to address the current challenges by analyzing and summarizing the scoring trends in the digital printing module.

Current State of Digital Printing Color Matching

In recent years, it has been observed that many participants in the Printing and Media Technology project focus predominantly on traditional offset printing modules, neglecting the digital printing module. This has led to a significant loss of points in this module, evidenced by the following issues:

-

Incomplete Color Matching Tasks: Participants struggle to complete the assigned color matching tasks within the specified time using the Heidelberg Versafire EV digital printing machine.

-

Irregular Operation of Digital Printing Equipment: Participants often fail to adhere to the strict standards and requirements of the WorldSkills competition due to improper operation of digital printing equipment during the contest.

-

Color Deviation Beyond Standards: A considerable number of participants exhibit color deviations beyond the specified standards, affecting their overall scores.

Analysis of Low Scores in Digital Printing Color Matching

The analysis reveals several factors contributing to low scores in digital printing color matching:

-

Insufficient Training Intensity: Participants often lack proficiency in operating digital printing equipment, leading to delays in tasks. Insufficient familiarity with equipment functions and the need for repeated confirmations of steps affect the quality of task completion under competitive pressure.

-

Noncompliant Operation of Digital Printing Equipment: Participants focus on the process but overlook the standards and quality of each step. Non-standard operations, such as insufficient test page prints and failure to calibrate EyeOne before measuring color deviation, negatively impact color accuracy.

-

Nonstandard Color Matching Procedures: Failure to follow the standard operating procedures of the Heidelberg Versafire EV digital printing machine contributes to deviations in color matching accuracy.

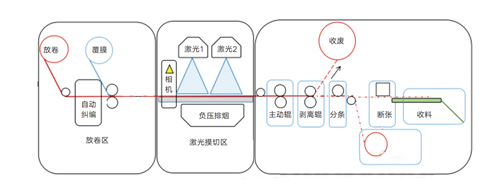

Steps for Digital Printing Color Matching

To address these challenges, the following steps outline a comprehensive and standardized approach to digital printing color matching:

- Load Correct Paper:

Use copperplate paper for calibration.

Ensure paper size and surface quality meet specifications.

- Set Paper Parameters:

Input paper dimensions, thickness, and type into the equipment, emphasizing correct selection of copperplate paper. 3. Create Calibration and Print Test Pages:

Create a calibration specifying a screen ruling of 175 lines. Print at least three test pages, using the manual measurement function. 4. EyeOne Scan Calibration Test Page:

Calibrate EyeOne before scanning the test page.

Place a white sheet under the test page during scanning.

5.Compare Scan Values with Standards:

Verify scan density on the device, ensuring it is within a 5% margin of error from the standard.

- Create ICC Profile:

Develop an ICC profile and print standard color charts (at least three copies). Disable all color management and conversion options in the digital printing equipment. 7. Scan Standard Color Chart with ISIS:

Scan the second-to-last sheet of the color chart using ISIS.

Ensure the chart is placed parallel and smooth along the paper edges.

- Check Scan Errors with Color Toolbox:

Use Color Toolbox to check scan errors. Reprint and rescan if errors exceed the specified threshold. 9. Import and Apply ICC Profile:

Import the ICC profile into the digital printing equipment. Re-select the device’s built-in color conversion tool. 10. Automated Color Matching:

After EyeOne calibration, input the target color for automatic color matching. Print a test page and measure the color accuracy. This method, developed through extensive student training and consultation with industry experts, has proven effective in achieving satisfactory results. While the approach may have its limitations, feedback and suggestions from peers in the industry are welcomed to further enhance its efficacy.

Click to learn more about book printing, sticker printing, medicine box, hardcover book printing, PE bag, Religious book printing, shopping bag printing, catalog printing, and printing in China.

Comments

No comments yet. Be the first to react!